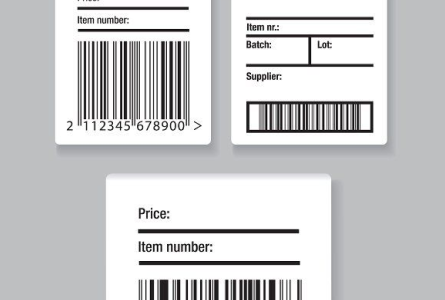

Barcode Stickers: What Makes Them Reliable and Readable

Barcode stickers may look simple, but they play a crucial role in product tracking, inventory management, and retail efficiency. Whether it's a supermarket, warehouse, or online store, a reliable barcode is the key to fast, accurate scanning and smooth operations. But what exactly makes a barcode sticker both readable and dependable?

“More than a price tag — it's your brand's first impression. Small in size, big on impact.”

It starts with quality printing. Barcodes must be printed with high contrast and precise alignment to ensure scanners can read them quickly, even in fast-paced environments. Poor printing, smudging, or low-resolution output can cause read errors, slow down operations, or even lead to stock mismatches. This is why choosing the right printer and materials is essential.

Material choice is equally important. Barcode stickers must withstand the conditions of their environment — whether that's exposure to moisture, heat, friction, or chemicals. Using the right adhesive and surface (like thermal labels or synthetic materials) ensures the barcode stays intact and legible throughout the product’s lifecycle.

Design also plays a part in readability. Proper sizing, quiet zones (blank space around the barcode), and avoiding distortion are all critical. Even a perfectly printed barcode can fail if it’s stretched, shrunk, or placed on a curved surface without care. Testing your barcode before mass production helps catch these issues early.

In short, barcode stickers are more than just labels — they’re data carriers that keep your operations flowing smoothly. With the right combination of design, materials, and printing precision, you can ensure your barcodes do their job: scan easily, last long, and support your business without a hitch.

Leave a Reply